The Ashkeeper making process:

I create my work from various types of high fired porcelain that is manufactured in Australia. I employ a combination of slip casting* and hand building techniques to create my handmade Ashkeepers. I utilise slip casting in the initial stages of creating my Ashkeepers and the subsequent stages of creation are done by hand.

*Slip casting – made with liquid clay in a plaster mould.

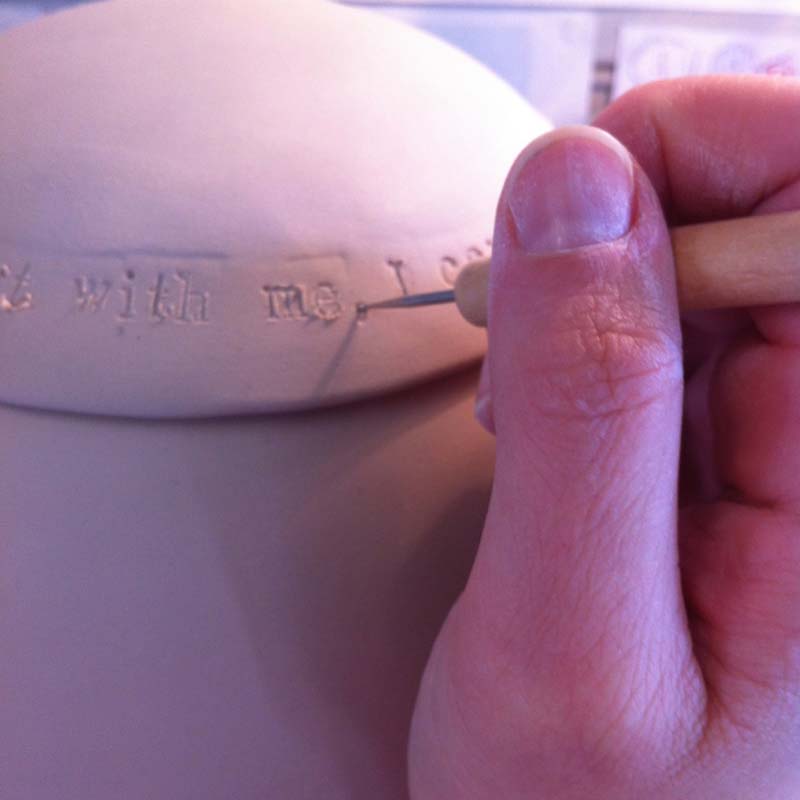

Step by step:

- First step begins with preparing slip casting material for the correct consistency for the Ashkeepers.

- Slip is poured into plaster mold, a stop watch begins to count the minutes – timing is very important to allow for correct thickness of each Ashkeeper (for strength and durability).

- After the Ashkeeper is removed from mold (once it is firm enough to remove, often 12 hours post pour), I check for quality, appearance and structure. The footring is attached to the base of the Ashkeeper and the flange is attached to the underside of the lid. It is then set aside to slowly dry until it reaches it’s leather hard stage.

- Now leather hard, the trimming and cleaning process begins by removing the mold casting lines on the leather hard piece. I inspect the piece again and then set it aside to dry until it reaches its bone-dry state. This drying process is slow and can take 3-4 weeks!

- Once bone dry, it is placed in the kiln to be fired up to 950 degrees. This firing takes up to 15 hours to reach temperature and around 20 hours to cool. After the first firing process is complete, the Ashkeeper is no longer clay, it has now reached its bisque state and has transformed into ceramic material.

- Now the Ashkeeper has been bisqued, I then take it out of the kiln (once cooled) approximately 24 hours later and the Ashkeeper is inspected once more, checking for any imperfections that may have developed during the bisque firing. Once the Ashkeeper has been 100% cleaned, the bisqued piece is set-aside to where I will glaze the Ashkeeper.

- When the glaze process is finished, I inspect the Ashkeeper, looking at the thickness of the glaze. Now the addition of colourful designs take place. Hand painting onto the surface of each Ashkeeper is a lengthy process and can take up to 12 hours to complete one piece. I examine the overall artistry of the Ashkeeper before it is placed back into the kiln for the second and final firing. The glaze firing lasts around 16 to 18 hours and reaches temperatures of approximately 1280°C.

- Now the Ashkeeper has completed the glaze firing, I take it out of the kiln (one cooled) approximately 24 hours later and examine the piece again. Finally, the Ashkeeper is lightly sanded all over for an extra smooth finish. It is then carefully packed into the Ashkeeper box and is hand delivered (local area) or posted out to you.